As I mentioned last week, I’ve been thinking a lot about agtech. It’s honestly unavoidable when you spend as much time as I have lately digging into the world of vertical farming. As I learned pretty quickly, things balloon outward into the many facets of the food supply chain. All of the pieces are inexorably linked, and food is so completely foundational to virtually every aspect of life.

This was one of those weeks with a flurry of robotics news, and food was a constant theme through much of it. What strikes me about it is something that’s been apparent for anyone who has followed the space with any frequency — robots and automation have the potential to profoundly impact every stage of the process. That includes everything from how food is grown to how we consume it.

The latest news demonstrates some key steps in that cycle. Obviously there are a lot of points in between worth highlighting, but just drawing on the headlines that have popped up since the last one of these columns, we can start building a pretty convincing skeletal structure here.

Image Credits: Bryce Durbin/TechCrunch

Don’t forget to sign up to get the upcoming free newsletter version of Actuator delivered to your inbox.

I actually touched on Iron Ox in last week’s column as an example of a company producing robotics for the explicit purpose of indoor farming. I guess I jumped the gun a bit, as it has since highlighted a new robotic system designed specifically for that purpose. As I noted previously, Iron Ox isn’t a vertical farming company; rather, it functions closer to a traditional indoor/farm greenhouse.

Image Credits: Iron OX

What sets it apart from those older models, however, is the way in which robotics and technology serve as its backbone. Nowhere is that clearer than with Grover, a mobile robotic system designed to move grow trays for monitoring and eventual harvesting. Says CEO Brandon Alexander:

We are applying technology to minimize the amount of land, water and energy needed to nourish a growing population. Our short-term goal is to mitigate the impact of climate change on the agriculture system. And we won’t stop until we achieve our long-term mission of making the produce sector carbon negative.

Image Credits: Miso Robotics

Miso Robotics also announced a new robot this week — or, rather, an update to its old model. The company has been piloting Flippy in select White Castles for a bit now, and just announced a version 2.0 of the fast food robot based on kitchen staff feedback. Unsurprisingly, workers’ biggest request was that Miso make the hamburger-flipping robotic arm more capable. Here’s Miso’s CEO Mike Bell:

Like all technologies, Flippy 2 has evolved significantly from its predecessor, and we are extremely grateful for the insights collected from White Castle to truly push its development forward in a real restaurant environment. Flippy 2 takes up less space in the kitchen and increases production exponentially with its new basket filling, emptying and returning capabilities. Since Flippy’s inception, our goal has always been to provide a customizable solution that can function harmoniously with any kitchen and without disruption.

Image Credits: Nuro

Autonomous mid- and last-mile robotics have been waiting in the wings to disrupt food delivery for some time now. In recent years, Nuro has shot to the top of that list, courtesy of partnerships with big names in food and grocery delivery like Domino’s, Kroger and Walmart. The money hasn’t hurt either.

Nuro this week announced a fresh $600 million raise, bringing the Mountain View-based firm’s funding north of $2 billion, while giving it an $8.6 billion valuation. The latter represents a 72% increase over this time last year. The Series D was led by Tiger Global Management. Co-founder and president Dave Ferguson told TechCrunch, “With the boost of this new funding, we’re turning our focus to commercializing and scaling the production of our third-generation vehicle at our new facility in Southern Nevada.”

That manufacturing plant is set to be completed at some point next year.

Image Credits: Ottobock

They’ll no doubt want to look into robotic exoskeletons to help ease the strain of human employees. Big news in that world, as German medical device maker Ottobock announced plans to acquire SuitX. The UC Berkeley spinout was founded by mechanical engineering professor Homayoon Kazerooni, who also founded Ekso Bionics.

Like Ekso (and, for that matter, many in the space), SuitX’s exoskeletons serve dual functions: work assistance and medical. The walking assistant Phoenix suit plays well into Ottobock’s current offering. SuitX has also been piloting Boost Knee, a robotic knee brace. Says Kazerooni:

This step is a success not only for SuitX but also for the University of California, Berkeley, where entrepreneurial endeavors are fostered to their greatest extent for the good of humans worldwide. I’m looking forward to bringing our technologies to communities internationally with Ottobock for better quality of life.

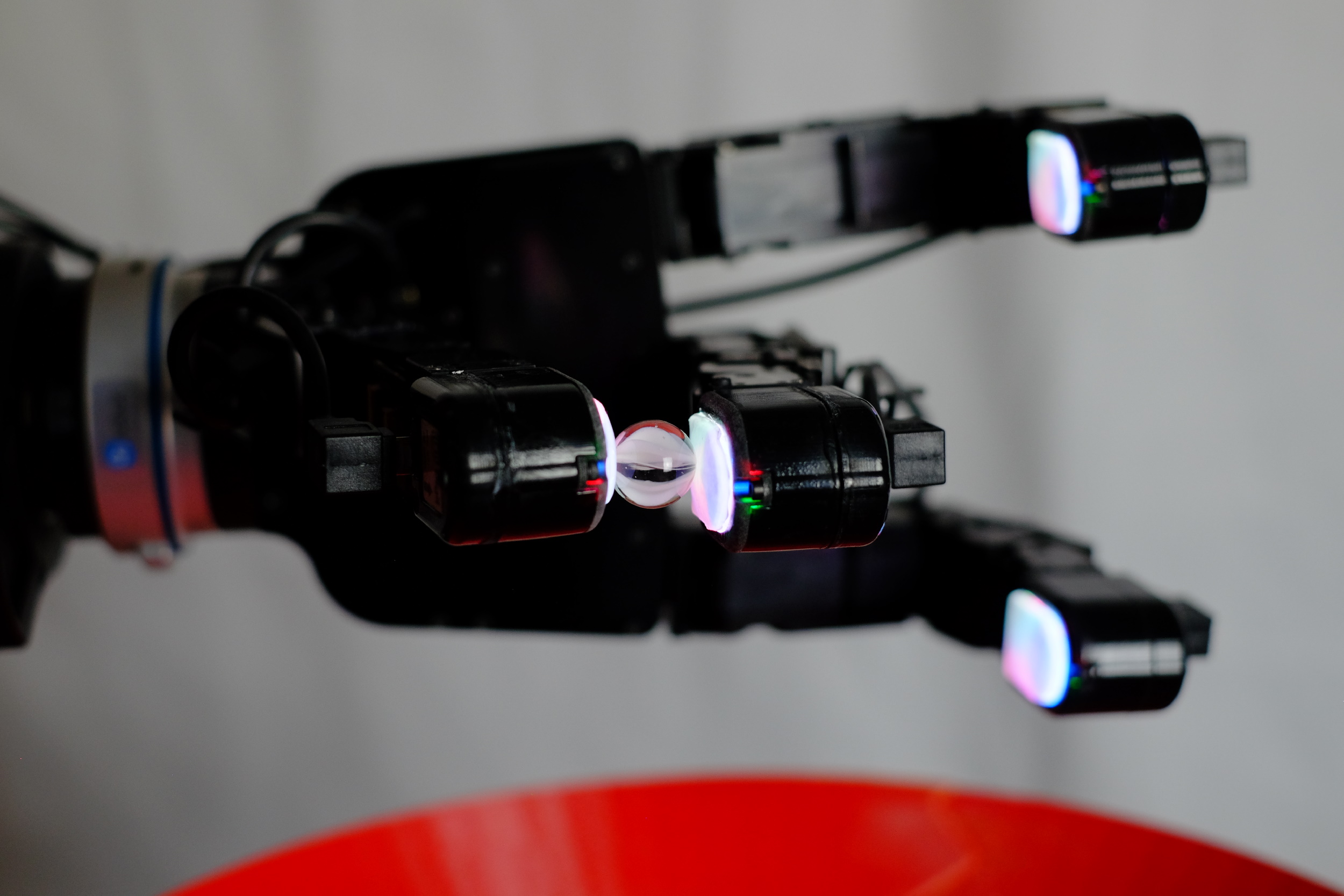

A robotic hand with DIGIT pads holds a marble between its fingers. Image Credits: Facebook

Buried in the veritable metaverse of Meta news this past week was this announcement from Facebook AI Research and CMU, which have been working on a robotic skin. A strange fit for Facebook to be certain, though who knows, a tacticity sensing synthetic skin could one day play a role in the aforementioned metaverse. For now, however, it’s an interesting look into how roboticists might expand the sensing capability of machines.

Image Credits: Roboat (opens in a new window)

This MIT CSAIL project seems to go beyond interesting experiments. Roboats are self-driving water taxis that the department has already begun to deploy in Amsterdam canals. Here’s CSAIL head Daniela Rus on the project:

We now have higher precision and robustness in the perception, navigation and control systems, including new functions, such as close proximity approach mode for latching capabilities, and improved dynamic positioning, so the boat can navigate real-world waters. Roboat’s control system is adaptive to the number of people in the boat.

And one more for the road. Boston Dynamics’ latest warm and cuddly robotic dog PR push finds Spot emulating The Rolling Stones’ “Start Me Up” music video to mark its 40th anniversary.